Implementing healthy interior practices is essential in commercial buildings, as it fosters a safe and comfortable environment for the occupants. The practices help in optimizing the operations of the buildings and, at the same time, also contribute to the sustainability of the complex setup. It is mandatory for commercial buildings to abide by the building codes and environmental regulations outlined by the regulatory bodies to ensure the safety, efficiency, legal compliance, and sustainability of the buildings. Here, HVAC systems play a crucial role in incorporating best practices in commercial settings by exercising energy efficiency and improving the indoor air quality (IAQ) of the space. The systems strategically maintain and extend the lifespan of the facility in the long run.

Installing advanced technologies such as VFDs, ERVs, building automation systems, etc., into the HVAC systems can help in driving the energy efficiency of the buildings. The variable frequency drives (VFDs) exercise precise control of the systems and modulate the energy consumption. Additionally, energy recovery ventilators (ERVs) optimize ventilation by exchanging heat and humidity between incoming and outgoing air. Dwelling in smart technologies in building automation systems, energy management strategies are employed that monitor and regulate the HVAC systems on the basis of occupancy patterns. All the factors together contribute to a significant saving of energy, translating to a reduction in the operational costs of the building.

Modern HVAC systems focus on improving the indoor air quality (IAQ) of the building. Enabling proper ventilation, and filtration, and implementing humidity control, provides a healthier and more comfortable IAQ for the occupants of the building. Installing Treated Fresh Air Handling (TFA) systems is beneficial for the removal of pollutants, allergens, and contaminants from space. By introducing fresh air into the room, the systems bring about the solution to pollution with dilution.

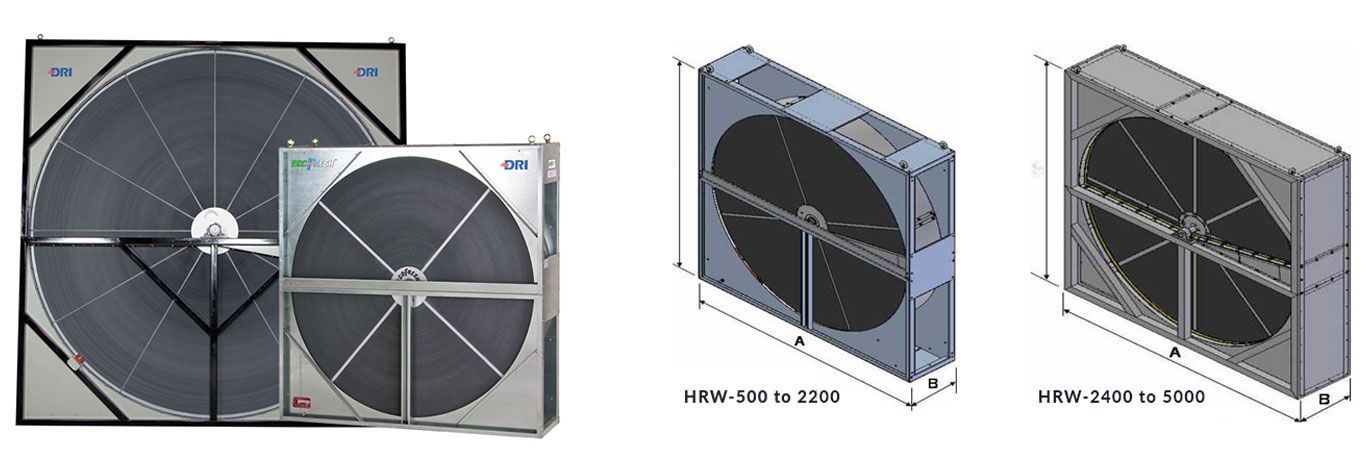

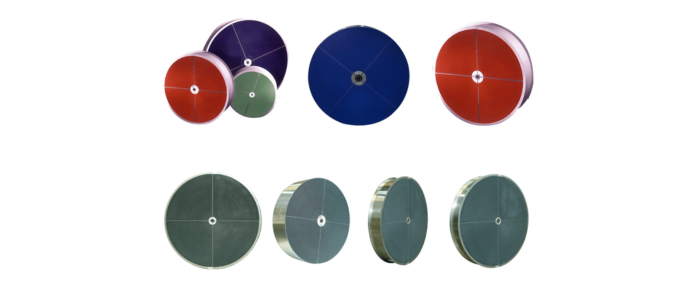

To ensure the ventilation standards are met, TFA conducts the preconditioning of outdoor air to provide fresh air into the room. The systems are involved in filtration and treatment of air before it is introduced into the room, as a result, the air circulating within the room is clean and healthy. Apart from improving IAQ, the TFA also comes with the proficiency to recover both sensible and latent energy with the help of energy recovery wheels, which play an instrumental role in minimizing energy utilization and go a long way in controlling humidity as well.

In the pursuit of enhancing IAQ in a commercial setting, monitoring the humidity level is also essential to abide by best practices. Humidity control is essential for a healthy indoor environment as it harbors the growth of mold, bacteria, and fungi, responsible for giving rise to a range of respiratory issues like asthma, bronchitis, and allergic reactions. The advanced Dedicated Outdoor Air Systems (DOAS) come in handy for monitoring humidity levels, facilitated by unique passive dehumidification wheels. The technology executes adequate ventilation of the space to replenish the fresh air and reduce the pollutant level in the air. The maintenance of optimal humidity levels significantly contributes to alleviating the discomfort due to excess moisture. In addition to improving the IAQ, it creates a pleasant environment for driving the productivity of occupants by reducing the instances of lethargy and health issues in them.

In turn, the HVAC systems promote the eco-friendly operation of the building. Demonstrating compliance with energy efficiency, they play an instrumental role in curtailing greenhouse emissions of the facility. Boosting sustainability, the buildings are in alignment with LEED, ASHRAE, ASSOCHAM, Indian Green Building Council codes, and other energy certifications.

It is important to conduct regular maintenance of the HVAC systems to drive greater longevity and reliability of the building. Failing to perform the maintenance can severely impact the lifespan of the system and ultimately disrupt the building’s operation. Systems in good condition save a lot of operational costs and prevent the sudden breakdown of the systems. Employing predictive maintenance tools and software in the form of smart sensors, regular system upgrades, and integration of advanced technologies with Building Management Systems (BMS) can help in the early detection of any issue or error.

Looking at the role of HVAC systems in abiding by the best practices of commercial buildings, industry players can further upscale the offering by installing technologically advanced systems in the building. AI-driven systems or IoT-powered systems enable centralized monitoring, data storage, etc., exercising enhanced performance of the building.