Inspired by the ancient art of Cooling

Developed in Asia, for Asia, and the humid regions around the globe.

What is a Chilled Beam?

Chilled Beams are room air recirculation devices, which are used to cool and ventilate spaces wherein user comfort and good indoor air quality is desired and valued; typically in commercial office spaces, hospital patient rooms, hotel rooms, classrooms, and laboratories. Chilled beams also supplement the flexible use of available space, and are used where the primary air is dehumidified. DRI's range of EcoBeam has a higher induction ratio and, therefore, the primary air volume is reduced and the supply air needs to be dehumidified to become dry enough to carry out all internal moisture loads. When paired with the DOAS, the chilled beam system ensures reliable and energy-efficient system operation

Chilled Beams

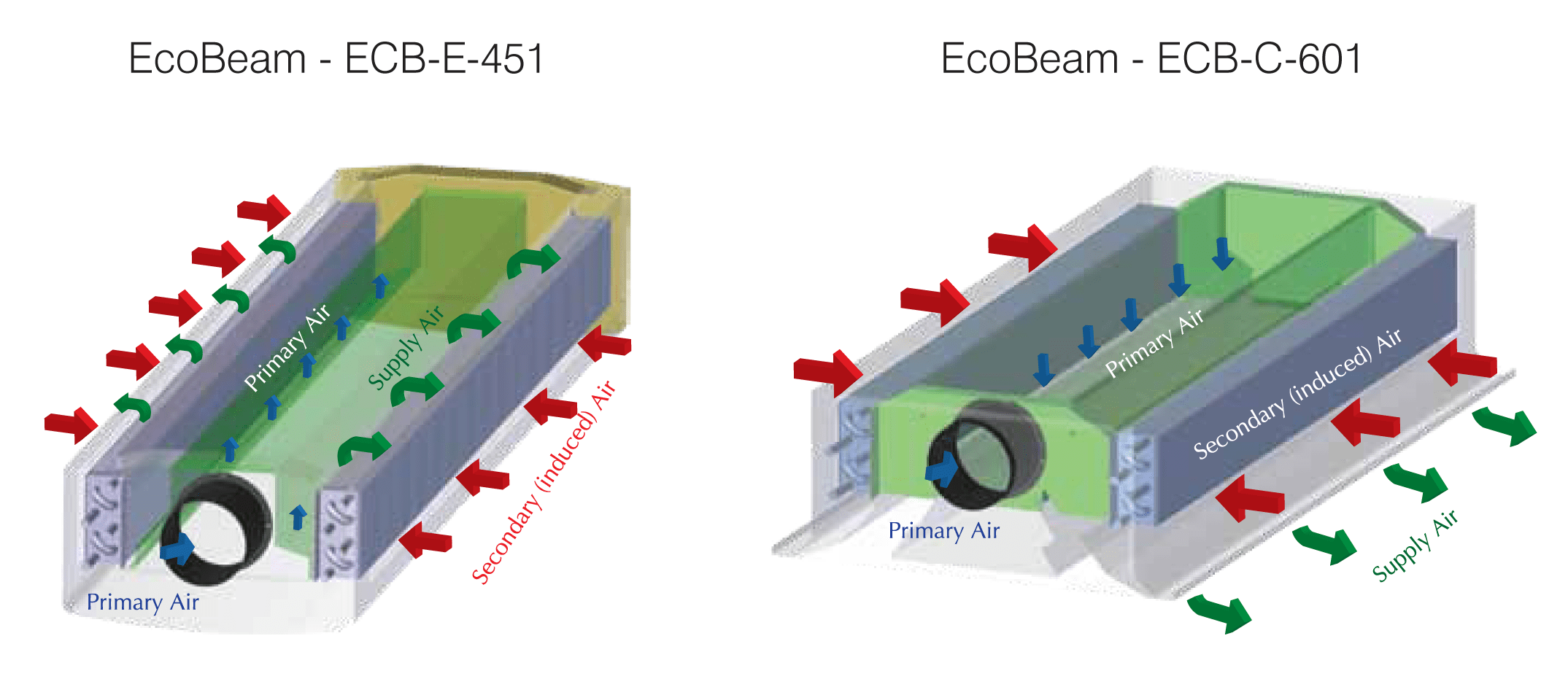

Active chilled beams are connected to both the ventilation supply air ductwork, and the chilled water system. The main dedicated outdoor air-handling unit supplies primary air into the rooms through the chilled beam. Primary air supply induces secondary air (room air) to be recirculated through the heat exchanger of the chilled beam. In order to cool the room cooled (15 -18° Celsius) water is cycled through the heat exchanger. The cooling output of the active chilled beam is depending on the amount of secondary air induced via a heat exchanger and the difference between room air temperature and average water temperature. Room temperature is controlled by regulating the water flow rate through the heat exchanger. When desired, hot water (30-45° Celsius) can be used in this system for heating.

The EcoBeam solution we developed is based on the innovative and patented nozzle arrangement together with venturi. Both the ecoNozzle and eco venture design have been inspired by the old Indian architectural element ''Jali'', which has been used over the centuries to increase air movement in buildings. A nozzle is the ''Engine'' of an active chilled beam to create room air circulation, while the venturi is a funnel, where the velocity of the air increase as the cross-sectional area decreases.

Case Study: One building - four different HVAC Systems

The energy efficiency of four different HVAC systems was simulated in three different cities of India. Chilled Beams system provides the most energy-efficient solution viz; 20-25% less energy is used than in the traditional system. In case, EcoBeam is integrated with DOAS system, further energy can be saved.

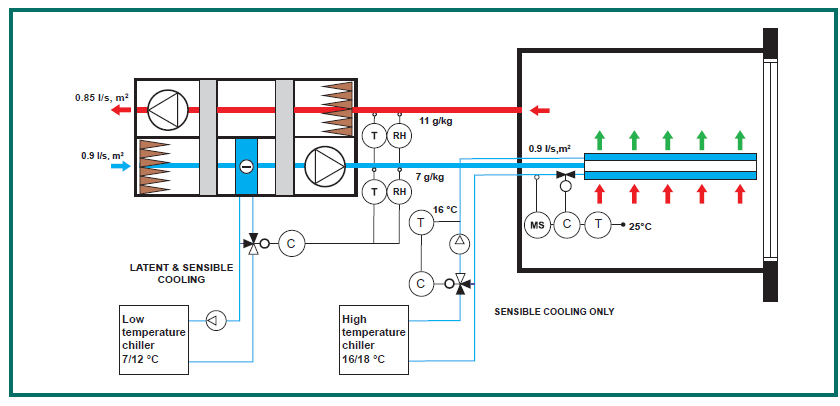

Pairing EcoBeam with DOAS

In a typical chilled beam application, the primary air volume is increased by about 50% of ASHRAE 62.1 + 30% (LEED requirement) to enable high enough secondary air circulation via a heat exchanger. This means increased fan energy and bigger space requirement of ducts, as higher air volumes are distributed in the building and also reduced air quality as a. 30-50% of air is recirculated.

As EcoBeam has a higher induction ratio, less primary air is needed to induce the room air and therefore building can be designed based on fresh air requirement only. This also allows using DOAS (Dedicated Outdoor Air System) units for air handling with integrated energy recovery and moisture removal. As the primary air volume is reduced, the supply air needs to be dehumidified to become dry enough to carry out all internal moisture loads. This can be ensured with DRI Ultima, where a double-wheel with a cooling coil is able to remove enough moisture from primary air.

Operation Schematic of DOAS with Active Chilled Beam System

EcoBeam range have been developed in India for Asia and high humid areas around the world. The product performance is an outcome of thorough research and numerous studies using technologies like Computational Fluid Dynamics (CFD) and shadow graph. A state-of-the-art test facility has been built for testing chilled beam performance based on both Eurovent and AHRI testing procedure. It can also be used for application testing.

Chilled beams can be used in buildings where outdoor air is treated (dehumidified) before supplying it into spaces and infiltration of outdoor air is in control. Also the internal moisture (latent) loads need to be moderate and primary air volume sufficient to avoid condensation. Therefore, the typical applications are:

In an office building, chilled beam systems provide several benefits. The lower supply air volume provides significant energy savings without influencing the comfort of users. In addition, the smaller infrastructure required to move lower air flow allows for small plenum spaces, translating into shorter floor-to-floor construction or higher ceilings. In case dedicated outdoor air system with good filtration is used, the indoor air quality is also improved.

Hotel rooms can also benefit from chilled beam systems. Fan power savings come from elimination of fan coil units, as a central air handling unit can have a lower total specific fan power. Also, less maintenance is needed inside the hotel room due to removal of the condensation pipes and filter.

Schools can benefit from chilled beam systems as the primary air is only used for providing good air quality for people and extra heat is removed with water. Therefore, the benefits of a lower supply air volume are reduced fan power, lower plenum height, reduced reheat requirements and noise levels.

In the hospital patient rooms, the room air temperature can be controlled to desired level without the need to increase the air volumes. When fully cleanable models are used, the high hygiene requirements of hospitals can be met.

In sensible load driven laboratories where the supply air rate is driven by the internal gains (such as refrigerators, testing equipment, etc.) as opposed to the exhaust requirements, chilled beam systems can offer significant energy savings.