Excess humidity in indoor environments can lead to various issues, from mould growth and structural damage to reduced indoor air quality and discomfort. Conventional dehumidifiers have been relied upon to address these challenges, but they often come with limitations regarding energy efficiency and overall effectiveness.

However, with advancements in air treatment technology, innovative solutions like Active Dehumidification Wheels have emerged, providing efficient and reliable moisture control for various industries and settings.

At DRI Rotors, we are at the forefront of air treatment solutions, and our Active Dehumidification Wheels are designed to optimize indoor air quality while ensuring energy efficiency and cost-effectiveness. In this article, we will discuss the concept of dehumidification, introduce Active Dehumidification Wheels, and delve into the advantages they offer for effective moisture control.

Understanding Dehumidification

Dehumidification involves removing excess moisture from the air to maintain optimal indoor humidity levels. Excessive humidity can lead to many problems, including mould growth, corrosion, musty odours, and compromised indoor air quality. Conventional dehumidifiers typically rely on refrigeration or absorption to extract moisture from the air. Still, these methods may consume significant energy and may not be the most efficient solution for large-scale applications.

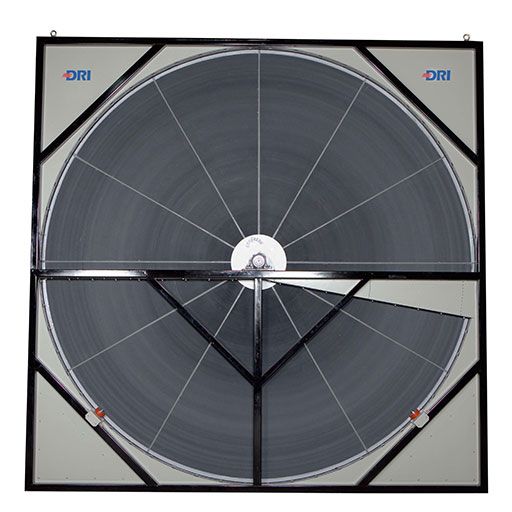

Introducing Active Dehumidification Wheels

Active Dehumidification Wheels are a revolutionary solution to combat humidity-related issues effectively. These wheels incorporate advanced technology to actively transfer sensible and latent energy between the incoming and outgoing air streams. Unlike traditional dehumidifiers, Active Dehumidification Wheels work on a regenerative cycle, making them highly energy-efficient and cost-effective.

Advantages of Active Dehumidification Wheels

Energy Efficiency and Cost-Effectiveness: Active Dehumidification Wheels leverage the energy from the outgoing air to pre-condition the incoming air, significantly reducing energy consumption compared to conventional dehumidifiers. The energy-saving potential of these wheels can lead to substantial cost reductions in the long run.

Improved Indoor Air Quality and Comfort: By maintaining optimal humidity levels, Active Dehumidification Wheels prevent mould and bacteria growth, ensuring better indoor air quality and a healthier environment for occupants. Moreover, they enhance comfort by reducing humidity-related discomfort, such as sticky and clammy air.

Moisture Control for Preventing Mold and Bacteria Growth: Excess moisture in indoor spaces creates a conducive environment for mould and bacteria to thrive. Active Dehumidification Wheels prevent mould growth and microbial contamination, promoting a cleaner and safer environment.

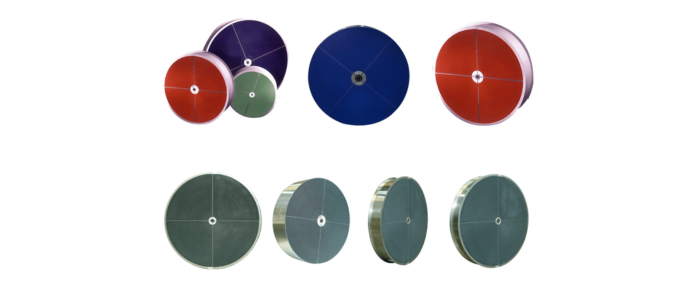

Applications Across Different Industries and Settings: Active Dehumidification Wheels find applications in various industries, including pharmaceuticals, food processing, museums, and data centres. They suit commercial and industrial settings, ensuring efficient moisture control in diverse environments.

DRI Rotors’ Cutting-Edge Solutions

DRI Rotors is a leading provider of air treatment solutions, and our Active Dehumidification Wheels are designed with cutting-edge technology to meet the unique needs of each application. We offer customization options, allowing businesses and industries to tailor the solutions to their specific requirements.

Our Active Dehumidification Wheels have been successfully installed in various projects, showcasing their effectiveness in moisture control and energy efficiency. With a team of experts in air treatment technology, we strive to provide state-of-the-art solutions that deliver outstanding performance and reliability.

Integration with HVAC Systems Active Dehumidification

Wheels can seamlessly integrate with existing HVAC system s, enhancing their overall efficiency. The wheels contribute to energy savings and extend equipment lifespan by reducing the workload on HVAC equipment. Combining Active Dehumidification Wheels with HVAC systems results in a comprehensive air treatment solution that ensures superior indoor air quality.

Environmental Benefits

At DRI Rotors, we are committed to environmental responsibility, and our Active Dehumidification Wheels align with sustainable building practices. The energy-efficient operation of these wheels reduces carbon footprint and supports green building certifications. Businesses can contribute to environmental conservation and sustainable practices by choosing Active Dehumidification Wheels.

Maintenance and Support

DRI Rotors provides comprehensive maintenance support to ensure Active Dehumidification Wheels’ longevity and optimal performance. Regular maintenance practices are recommended to keep the wheels in top condition, and our expert team is available to assist with any technical inquiries or assistance.

The Future of Active Dehumidification Wheels

The future of air treatment technology holds exciting possibilities, and DRI Rotors is dedicated to continual innovation. We are actively exploring advancements in dehumidification technology further to enhance the efficiency and effectiveness of Active Dehumidification Wheels. Our commitment to research and development enables us to shape the future of moisture control solutions.

Conclusion

Active Dehumidification Wheels have revolutionized how we address indoor humidity-related challenges. These wheels offer innovative solutions for effective air treatment with their energy efficiency, superior moisture control capabilities, and versatile applications. At DRI Rotors, we are proud to be at the forefront of this technology, providing cutting-edge solutions that optimize indoor air quality and contribute to a sustainable future. Whether for commercial, industrial, or specialized applications, our Active Dehumidification Wheels offer a reliable and efficient moisture control solution for any setting.