Desiccant Dehumidifiers: Efficient and Earth-Friendly Moisture Control Solutions

Most people are familiar with the standard refrigerant-based models when it comes to dehumidifiers. However, a lesser known yet highly effective alternative is the desiccant dehumidifier. Unlike traditional refrigerant dehumidifiers, these innovative devices use a desiccant substance to remove moisture from the air, making them more energy-efficient and environmentally friendly. In this blog post, let’s discuss the working principles of desiccant dehumidifiers, their unique adsorption process, and the various industries where they excel in providing effective moisture control.

What is a Desiccant Dehumidifier?

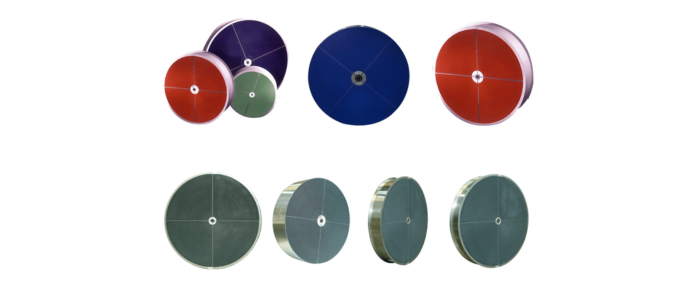

Desiccant dehumidifiers operate without refrigerant and compressors, employing a desiccant wheel to cleanse moisture from the air. Unlike conventional dehumidifiers, such as low-grain refrigerant (LGR) units, desiccant dehumidifiers function at significantly lower temperatures and offer quieter operation. These eco-friendly units also operate more efficiently, resulting in reduced power consumption.

Understanding Adsorption

The desiccant dehumidifier’s effectiveness lies in adsorption, wherein water molecules in damp air are attracted and held on the surface of the adsorbent (desiccant). This is distinct from absorption, where the material absorbs moisture into its structure. For example, activated carbon and silica gel, commonly used in air filters and freshness packets, utilize adsorption to remove odours and moisture.

How Does a Desiccant Dehumidifier Work?

Desiccant dehumidifiers comprise a wheel coated with silica gel, a drive motor and belt, a small heater, and a blower. The process begins when damp air is drawn into the dehumidifier, passing through the desiccant wheel, where moisture is adsorbed on the silica gel surface. Most dry air is then expelled back into the space, while a portion is directed through the heater, becoming regeneration air. This warm, dry air is then passed through the desiccant wheel to release the collected moisture, regenerating the silica gel.

Their adsorption process, precise humidity control, and ability to work efficiently in low temperatures make them a preferred choice for different industrial applications. From pharmaceutical manufacturing and food processing to electronics and marine environments, desiccant dehumidifiers ensure a comfortable and moisture-free indoor environment, protecting assets and preserving the quality of products. Embrace the cutting-edge technology of desiccant dehumidifiers to optimize indoor air quality and combat moisture-related challenges effectively.

Benefits of Desiccant Dehumidifiers:

Desiccant dehumidifiers offer a wide array of benefits, making them a preferred choice for moisture control in various industrial, commercial, and residential settings. Let’s explore the advantages of these innovative devices that set them apart from traditional refrigerant-based dehumidifiers:

Superior Moisture Removal: Desiccant dehumidifiers are exceptionally efficient at removing moisture from the air. Their adsorption process allows them to attract and hold moisture molecules on the surface of the desiccant wheel, effectively lowering humidity levels in the indoor environment. Whether it’s a damp basement, a large industrial facility, or a museum housing valuable artifact, desiccant dehumidifiers ensure optimal moisture removal.

Effective in Low Temperatures: Unlike refrigerant-based dehumidifiers that struggle to perform in cold climates or low temperatures, desiccant dehumidifiers excel in such conditions. They can continue to function efficiently even at below-freezing temperatures, making them a reliable choice for spaces where maintaining low humidity levels is critical.

Precise Humidity Control: Desiccant dehumidifiers provide precise control over indoor humidity levels. This is particularly beneficial in pharmaceuticals, food processing, and electronics industries, where precise humidity control is necessary to maintain product integrity and quality. Achieving and maintaining specific humidity levels makes desiccant dehumidifiers an invaluable asset in critical processes.

Energy Efficiency: Desiccant dehumidifiers operate with reduced power peaks, producing energy-efficient performance. Unlike refrigerant dehumidifiers that require high power consumption during operation, desiccant dehumidifiers offer a more sustainable and eco-friendly solution for moisture control. This energy-efficient operation leads to lower utility bills and reduced environmental impact.

Environmentally Friendly: By using adsorption instead of refrigerant-based cooling, desiccant dehumidifiers are free from ozone-depleting substances, making them environmentally friendly. Businesses and industries seeking sustainable and green solutions can rely on desiccant dehumidifiers to fulfil their moisture control needs without harming the ozone layer.

Low Maintenance: Desiccant dehumidifiers require minimal maintenance compared to traditional refrigerant-based dehumidifiers. Since they do not have condensate or refrigerant to manage, there is no need for frequent emptying of water tanks or complex refrigerant system maintenance. This low maintenance aspect makes them ideal for applications in unattended or remote locations.

Versatility in Applications: Desiccant dehumidifiers find applications in various industries and spaces. They are effective in industrial processes, commercial buildings, warehouses, indoor growing facilities, museums, preservation and archives, pharmaceutical labs, and more. Their ability to lower humidity levels in hostile environments makes them an adaptable solution for various challenging applications.

Compact and Lightweight Design: Desiccant dehumidifiers are designed to be tight and lightweight, making them easy to install and move when needed. Their portability and versatility make them suitable for temporary moisture control in construction sites or emergencies.

Applications of Desiccant Dehumidifiers

Pharmaceutical Industry: Desiccant dehumidifiers are essential in pharmaceutical production facilities to maintain optimal humidity levels and protect product integrity.

Printing & Paper Industry: These units prevent moisture-related issues like clogging and bulking in printing and paper processes.

Marine Environments: Desiccant dehumidifiers are utilized in ship-building and marine environments to control humidity and prevent corrosion.

Food Production & Processing: Commercial food production facilities rely on desiccant dehumidifiers to maintain proper humidity levels and prevent spoilage.

Indoor Growing: Desiccant dehumidifiers are indispensable for indoor growing operations to control humidity during harvest drying and curing processes.

Storage and Packing Facilities: These units prevent mould growth and condensation in storage and packing facilities, preserving the quality of stored goods.

Unfinished Buildings & Construction Sites: Desiccant dehumidifiers effectively reduce humidity in construction sites and unfinished buildings, preventing damage to materials.

Electronics: These units help maintain the ideal humidity levels for sensitive electronic components.

Conclusion

Desiccant dehumidifiers are an innovative and effective solution for moisture control in various industries. Their adsorption process, precise humidity control, and eco-friendly operation make them a superior choice in challenging environments where low humidity is essential. From pharmaceutical manufacturing to indoor growing operations, desiccant dehumidifiers offer unmatched performance and efficiency. Embrace the benefits of desiccant dehumidifiers to ensure optimal indoor air quality and protect your assets from moisture-related issues.