Ahmedabad, 29th January 2020:- Delivering the keynote address at the 13th Confluence International Conference on Indoor Air Quality, Deepak Pahwa, Chairman Pahwa Group, shared with the attendees that the increased challenges maintaining IAQ ( Indoor Air Quality) in conditioned spaces with the increased outdoor air pollution. He expressed that today modern climate controlled interiors-offices, homes, malls, hospitals as well as bus stations, airports-was a given , where people spend more than 80 percent of their time.

In his keynote, Mr Pahwa traced the journey introduction of IAQ as a concept in India from the time the concept was introduced to the Indian HVAR&R industry by DRI, a Pahwa group company way back in 1991.

Enclosed conditioned spaces such as office complexes, malls, hotels, restaurants, auditoriums, heaters and various other buildings are dealing with not only contaminants/pollutants generated indors but also has to ensure outdoor pollution like like PM 2.5, PM10, VOCs as well other gaseous contaminants is not brought inside conditioned spaces through conditioning systems.

‘Now, more than ever, the need to monitor and improve indoor air quality is crucial,’ Pahwa said. ‘It’s also become easier given the focus on reducing outdoor air pollution as well as the emergence of cutting edge technologies to manage air quality indoors’.

According to Mr Pahwa, the growing awareness of air pollution and its deleterious impact on human health also focused attention on the need for monitoring and handling indoor air quality. With outdoor air as input, indoor air handling systems design needed to do more than merely cooling to heating, ventilation, and air conditioning. Often known by its acronym, HVAC is goes beyond providing thermal comfort to ensuring acceptable indoor air quality.

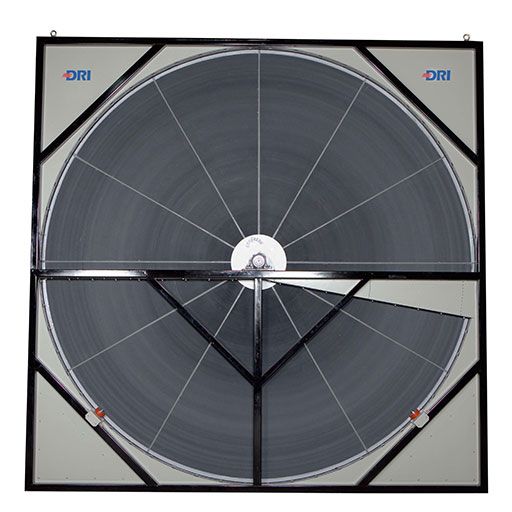

Elaborating on the latest technology in HVAC systems, Pahwa said they use desiccant technology that uses hygroscopic substances that suck moisture from the air and cool indoor spaces. One of the major benefits of the technology is the reduction in tonnage required for a given space with associated reduction in the use of energy and utility costs.

As such, it fits the bill as ‘a sustainable green technology that incorporates a concern of climate change, a crucial new awareness that seeks to limit the emission of greenhouse gases, including carbon dioxide, that are responsible for the phenomenon known as global warming,’ he added.

He lauded ‘the welcome tendency’ to deploy renewable energy solutions to the problem of poor indoor air quality. ‘Renewables’ provide a way to manage the costs of increasingly expensive and finite sources of fossil fuels. With growing awareness of the long term conundrums in the indiscriminate use of fossil fuels, urban planners have begun to look at options such as solar energy, natural building materials, and ecologically effective heating, ventilation, and air conditioning (HVAC) systems.

Referring to Pahwa Group’s experience with the deployment of HVAC systems globally, Mr Pahwa spoke of the company’s experience with the Beijing Olympics, where its flagship company, Dessicant Rotors International, installed air quality control systems at various sites including the Beijing Airport.

‘Working to very clear and stringent specifications, our indoor air handling systems helped save about 80 percent of the energy that is lost with outgoing air and facilitated an increase in the quantity of fresh air,’ Pahwa elaborated.

Mr Pahwa was honored at the conference for his pioneering work and tremendous contribution to the Indian HVAC and R Industry.

About Pahwa Group:

‘With Desiccant at its core, in relation to air’, the Pahwa Group is a group of knowledge based and technology driven companies offering advanced environmental control solutions to a wide array of companies. The Group is headed by Mr. Deepak Pahwa as the Group Chairman and employs a strong team of over 1400+ persons in 6 continents and has 10 manufacturing units. The core strength of all the group companies is concentrated in desiccant and desiccant-based technologies. Operating within a broad framework of ‘environment and energy’, the group companies are involved in manufacturing products like dehumidifiers, resin dryers, product dryers, gas phase filtration systems, energy recovery and fresh air treatment systems. Desiccant Rotors International (DRI) is a global provider of components, products and systems for Energy Recovery, Indoor Air Quality, Fresh Air Treatment, and Green Buildings. Desiccant Rotors International, Inc. (DRI Inc.) markets and sells energy recovery wheels and desiccant dehumidification rotors and cassettes in North America. The current installation base of DRI wheels in North America runs in the thousands. Our parent company, DRI, is the largest global provider of enthalpy wheels for air-to-air energy recovery. The DRI worldwide group has a global sales network extending to Brazil, China, Malaysia, Europe, South Africa, Philippines, Australia, Korea and India. DRI has a fully integrated ISO certified manufacturing facility with in-house coating, synthesizing, winding, metal working and surface finishing and world class test facilities for performance evaluation of enthalpy wheels and desiccant dehumidification wheels.