The Centre’s decision to push a year-round clean air plan in Delhi NCR regions for 2026 is a defining step shaping India’s urban breathability in the upcoming year. Introduced amidst the worsening pollution beyond hazardous levels, it marks a critical shift for tackling deteriorating AQI. It onlooks a transition from reactive, winter-centric strategies to more systematic and sustained action.

Where outdoor pollution is the major focus of the government, indoor air quality (IAQ) is the next frontier for ensuring holistic air management across cities and buildings. As per the directive by the Centre, it is mandatory for industrial clusters of the region to install air pollution control devices. Any form of non-compliance can result in closure of the industry. This calls for improvement of IAQ in large commercial and industrial spaces where modern buildings feature glass façades. Adopting a windowless design, there is hardly any scope for fresh air ventilation within the facility.

Leading to buildup of carbon dioxide and pollutants, the packed structure triggers recirculation of stale air, creating hazardous indoor environment for the occupants of the space. Prolonged exposure to poor IAQ leads to the development of a condition called Sick Building Syndrome, giving rise to severe health risks such as headaches, throat irritation, burning eyes, difficulty in breathing. It also impacts the cognitive function of the people, significantly declining their productivity, and accounts for increased absenteeism in them.

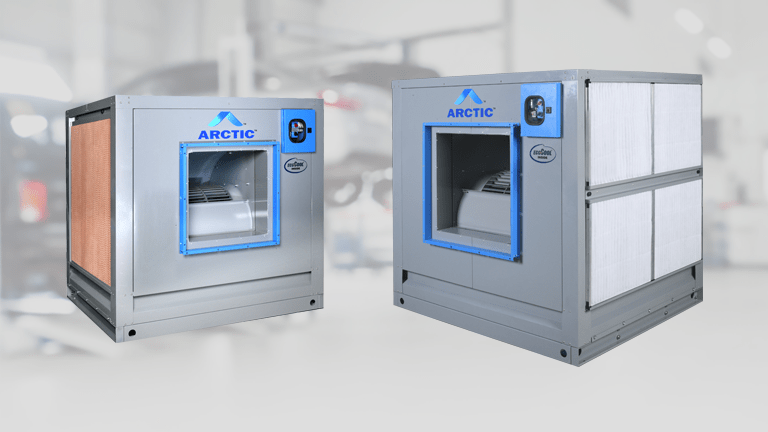

Owing to this, installing Air Handling Units (AHU) comprising of Treated Fresh Air Units (TFA) and Dedicated Outdoor Air Systems (DOAS) is a basic necessity in commercial spaces nowadays. It is only expected that the adoption rate of these advanced technologies will increase in the coming years. With the intensification of plunging air quality in urban setups, TFA systems are at the heart of protecting the indoor environment of the building.

Performing the preconditioning of incoming fresh air, the systems achieve the highest ventilation standards by introducing it to the enclosed facility. Driving the filtration and treatment of the air resists the entry of pollutants, allergens, and airborne contaminants into the room. Prolonged exposure to poor IAQ poses serious health risks. This makes it necessary for large commercial spaces such as malls, schools, offices, etc. to continuously improve the indoor air quality of the buildings.

Here, the role of TFA systems goes beyond providing optimal IAQ and aligns with energy efficiency goals at the same time. Being well-equipped with energy recovery wheels, it is proficient at reclaiming both sensible and latent energy from the exhaust air. This allows for achievement of ideal humidity and comfort without amplifying the energy demand of the building. Contributing to stable indoor environment, it gives an edge to the buildings all year round, isolating them from the impact of fluctuating outdoor conditions.

Responsible for efficient airflow, the systems significantly reduce the overall load on the conventional HVAC systems. Lowering the need for heating and cooling the space, it accounts for minimized energy consumption, translating to long-term operational savings.

Humidity is another factor determining healthy IAQ, as uncontrolled moisture triggers the growth of bacteria and fungi. It not just makes the indoor environment uncomfortable for the occupants but also has a damaging effect on the materials within the space. Here, TFA comes with the ability to monitor humidity levels and prevents the proliferation of microbes and eliminates the issue of static electricity.

Deploying Dedicated Outdoor Air Systems (DOAS) can further aid in controlling humidity by harnessing the power of passive dehumidification wheels. By introducing fresh, treated air into the room, it conducts the removal of indoor pollutants and limits the moisture to acceptable levels for eliminating unpleasant odour and occupant discomfort. Altogether, managing the RH levels, recovering energy, and mitigating cross-contamination, DOAS comprehensively improves IAQ.

As the country prepares for 2026, prioritizing clean air, there is a need to extend the conversation beyond outdoor air pollution and focus on IAQ as well. As people spend the majority of their time indoors, buildings with the ability to provide fresh air, control humidity, and drive energy efficiency are at the cusp of improving urban breathability.

Varun Pahwa (President) Desiccant Rotors International