With people becoming highly conscious about their health, there has been rising awareness around the poor IAQ in commercial spaces. Modern-day commercial spaces are generally glass skyscrapers exhibiting a complex and packed structure with no space of windows for accommodating air conditioning systems. Restricting any scope of fresh air ventilation, the facilities can significantly contribute to poor indoor air quality (IAQ), which can negatively impact the health of the occupants.

Spaces such as malls, hospitals, large office buildings, airports, and other facilities are generally huddled by a large number of people, which leads to the buildup of carbon dioxide and pollutants, responsible for poor IAQ within the space. The situation is further worsened by the air conditioning systems recirculating the stale air, making the indoor environment hazardous for the occupants. It can potentially give rise to a range of health issues entailing respiratory problems, allergies, and even serious conditions of cardiovascular diseases. Prolonged exposure to poor IAQ is also responsible for the development of a condition called Sick Building Syndrome, where people become susceptible to various allergies and life-threatening diseases. It also comes with the ability to affect cognitive function, giving rise to a decline in productivity coupled with increased absenteeism in a person.

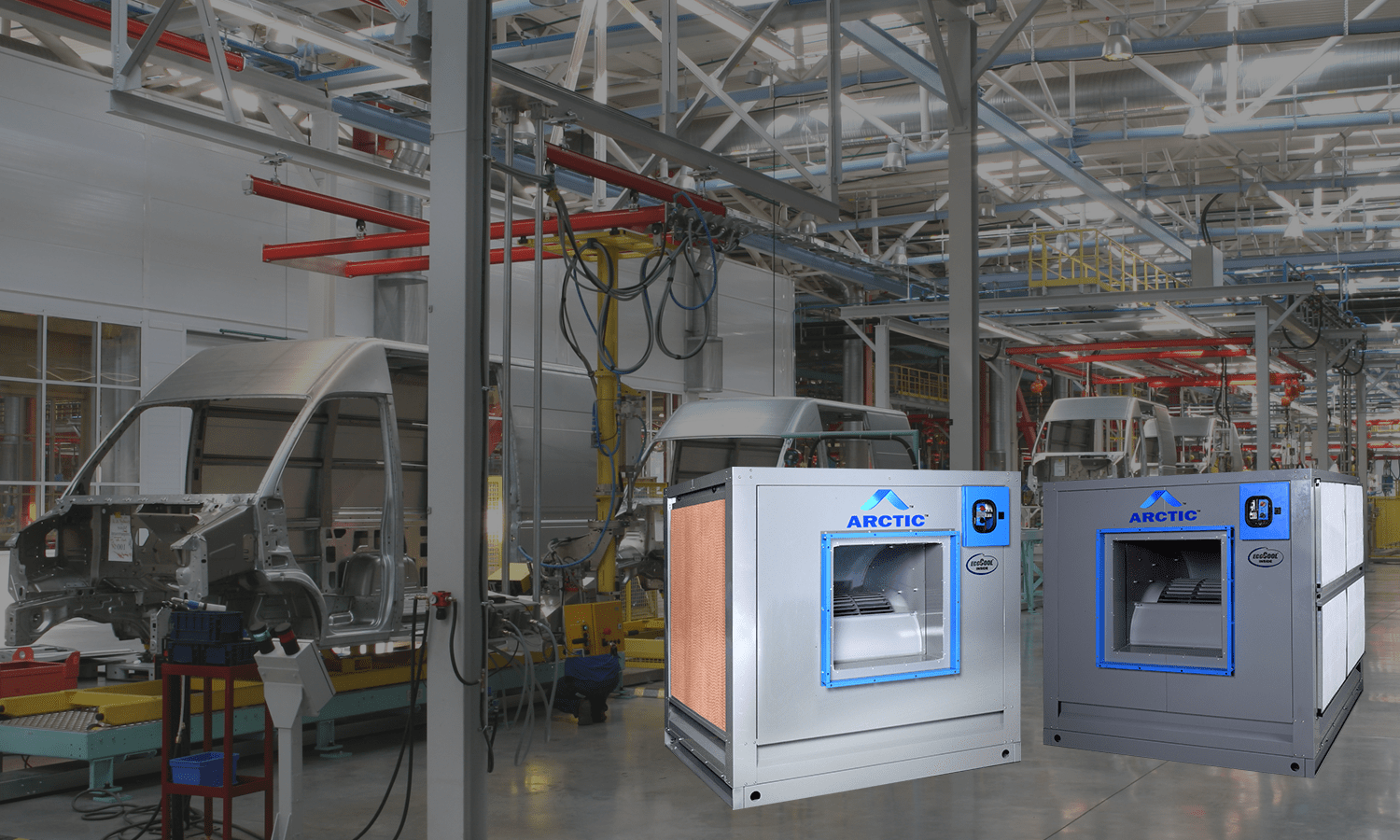

This necessitates the deployment of advanced technologies that work towards enhancing the quality of air in the commercial facilities. To achieve acceptable air quality, the industry should proactively consider installing Fresh Air Ventilation systems in tandem with the air conditioning units to provide comprehensive ventilation solutions within the space. Making use of Air Handling Units (AHU) entailing Treated Fresh Air Units (TFA) and Dedicated Outdoor Air Systems (DOAS) provides a viable solution for introducing fresh air into the space while reducing energy consumption, translating to a decrease in the operational cost of the building.

To achieve good air quality, employing Treated Fresh Air Handling (TFA) systems is essential. These systems precondition the incoming fresh air to meet ventilation standards and maintain excellent indoor air quality (IAQ).

By filtering and treating the air before it enters the space, TFA systems eliminate pollutants, allergens, and contaminants, effectively impeding the spread of airborne diseases. As a result, these units ensure a consistent supply of clean and healthy air, significantly reducing health issues associated with poor air quality. Additionally, TFA systems are equipped with energy recovery wheels, which recover both sensible and latent energy, contributing to improved IAQ, humidity control, and energy savings.

Another major advantage of the system relies on its ability to optimize indoor air quality round the year. Contributing to a stable and comfortable environment, it alleviates health risks and boosts the productivity of the occupants, irrespective of the weather conditions outside. Delivering fresh air continuously, it maintains air quality at acceptable levels for indoor settings. In educational institutes or offices, this plays a pivotal role in elevating the motivation and engagement of the people, resulting in overall better performance of the individuals.

In addition to this, TFA systems come with the ability to provide energy-efficient solutions. It is proficient at meeting the desired ventilation standards without amplifying the energy cost of the building. Striving to manage the airflow efficiently, it ensures appropriate circulation of fresh air, negating the excessive need of heating or cooling the enclosed space. As a result, the benefit is not just limited to energy savings but eventually translates to a significant reduction in the operational costs of the facility as well.

Elaborating on the advantages of the system, TFA can bring about a significant reduction in overall system capacity requirements. By handling and distributing the air efficiently, the system lowers demand for heating, ventilation, and air conditioning (HVAC) systems. Ultimately contributing to a reduction in the overall load of the system, it culminates in lowering the operational costs and energy consumption of the systems.

In the pursuit of improving the IAQ, people generally tend to overlook humidity. But maintaining the optimal humidity of the space is crucial for achieving the desired result. Moisture in the air is responsible for the proliferation of bacteria and fungi, which can impact the health of the person. Therefore, TFA aids in controlling humidity within acceptable limits and prevents the growth of microorganisms and the issue of static electricity. In the process of eliminating humidity from the air, it does not incur additional cost, making it a cost-effective solution for commercial spaces. In addition to ensuring the health and safety of the people occupying the space, maintaining proper humidity protects the various materials present in the space and preserves the longevity and reliability of the materials.

Here, the Dedicated Outdoor Air Systems (DOAS) can also be beneficial for addressing the issue of humidity. Well equipped with unique passive dehumidification wheels, it ventilates the space adequately by removing indoor air pollutants, monitoring humidity levels, and replenishing fresh air in the process. Managing the humidity level, it plays a pivotal role in addressing the issue of mold growth, unpleasant odors, and discomfort arising from excessive moisture. Resisting the accumulation of pollutants, odors, and contaminants, it supplies fresh air for a comfortable, healthy, and productive environment. Therefore, managing the RH (relative humidity) levels, maximizing energy recovery efficiency, and reducing cross-contamination provides a comprehensive solution for improving the air quality of the space.

Therefore, looking at the complexity of the commercial facilities, employing the systems can come in handy for optimizing the air quality. Looking at the wide gamut of benefits the systems have to offer, entailing pre-conditioning of incoming air, delivery of fresh air, energy-efficient ventilation, and humidity control, they are very likely to prioritize the health and safety of the occupants. And in the process, the systems also reduce the load on the HVAC systems, making them a viable and practical solution for large, complex buildings.