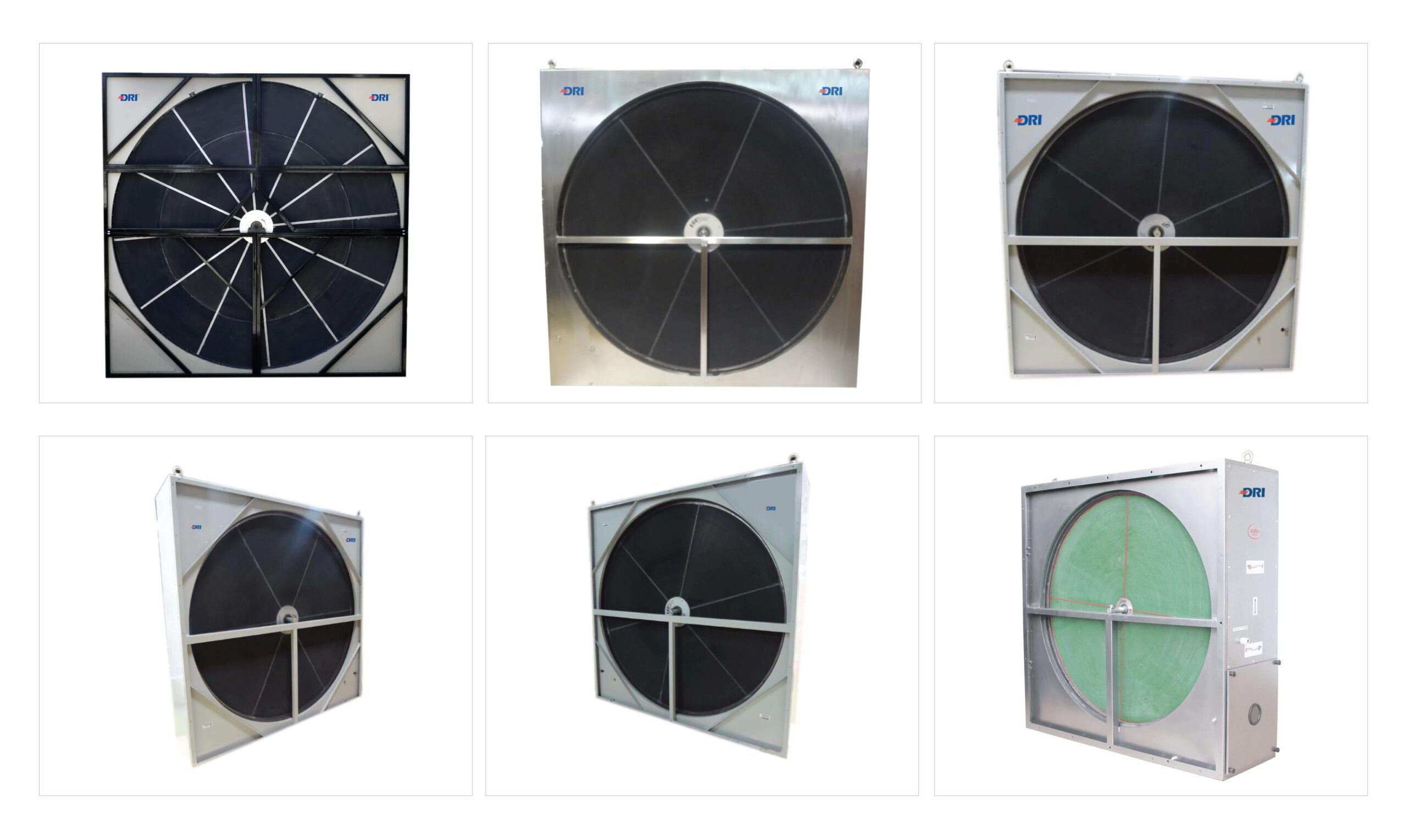

G3MA Passive Desiccant Dehumidification Wheels Patented

Achieve Optimum Dehumidification Without energy usage

Regenerates desiccant without additional energy usage

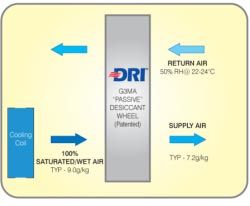

The unique G3MA "Passive" Desiccant Dehumidification Wheel (Patented) has the ability to be regenerated with the 50% RH room return air allowing for substantial moisture removal through dehumidification of the fresh air being supplied to the room.

DRI has established a reputation around the world for technology innovations and industry leadership in Fresh Air Treatment Products and Solutions which help maintain healthy IAQ (Indoor Air Quality) and also meet today's environmental challenges. DRI has played a pioneering role in innovating various new Fresh Air HVAC Systems. Our products are well suited to a wide array of applications in commercial spaces like hotels, hospitals, supermarkets, auditoriums, and all other conditioned spaces as well as conditioned manufacturing & processing areas like pharmaceuticals, food, electronics, etc.

The DRI G3MA "Passive" Desiccant Wheel (Patented) does not require thermal heat for regeneration. The unique "Passive" Desiccant Wheel has the ability to be regenerated with the 50% RH room return air allowing for substantial moisture removal through dehumidification of the saturated (100% RH) Fresh Air being supplied to the room.