DRI is the world's leading independent desiccant rotor and cassette manufacturer. DRI now has an installed base of hundreds of thousands of desiccant rotors on all continents over the last 23 + years. We are a reliable and trusted partner globally with over 40 years' experience in environment control solutions.

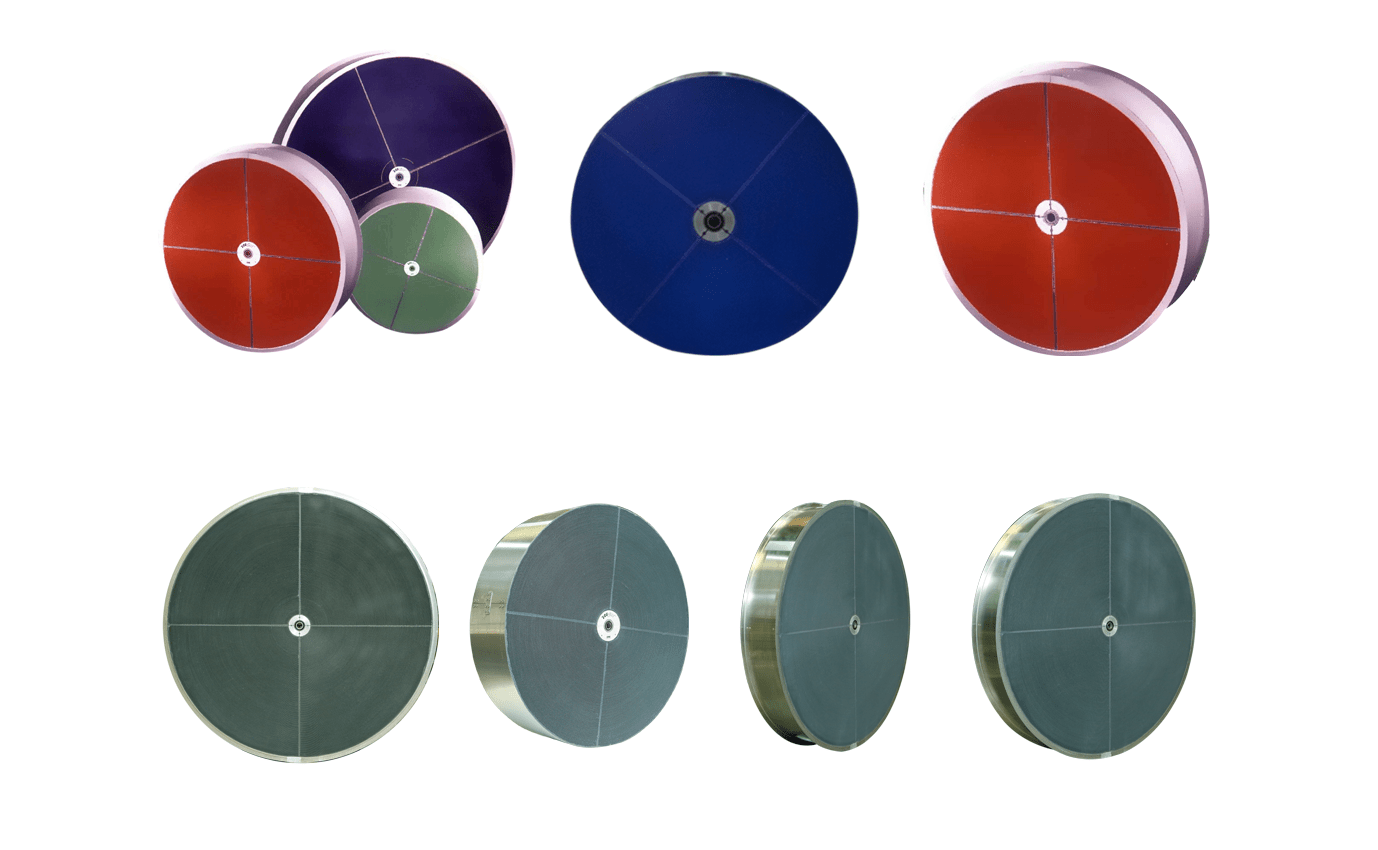

Our "Ecodry" desiccant rotors , are top of the line in performance and are available in a variety of combination of substrates and desiccants. We also offer desiccant rotor/wheels for replacement in existing systems. We have ability to manufacture these rotors in any diameter and depth that also with very precise dimensions which is must for replacement jobs. The rotors are highly adsorbent, non-toxic, non-flammable, fully water washable.

The media is pH neutral having in-situ synthesized metal silicate desiccant on an inert inorganic fiber substrate. The active desiccant material is at least 80% of total media weight. The surface of the media is edge hardened to ensure smooth surface thereby increasing rotor as well as seal life. Our standard rotors have perimeter flange so as to allow greater durability and to roll on the ground without damage. The rim of the desiccant rotors are in stainless steel as a standard as a large part of the applications are in the food and pharmaceutical industry.

We have multiple desiccant rotor options. Our standard MH range is used for the majority of dehumidification applications. We have an LH / DHP1 range for very low dew point requirements such as in the plastics industry and lithium cell/battery applications. We have another range for low-temperature regeneration. Also for commercial fresh air treatment applications, we have a patented product, a passive desiccant rotor regenerated based on room return air.

On the performance side, our desiccant rotors are better than any other media in the marketplace, especially when it comes to critical low dew point requirements.

Our desiccant rotors have unique advantages over everyone else-they are pH neutral. We do not use any acid during the media preparation or any burn-off process during manufacturing, hence the media is comparatively much stronger.

For commercial dehumidification applications, we supply unique G3MA "True Passive Dehumidification" wheels which allow substantial moisture removal through dehumidification of the fresh air being supplied to the room.

Desiccant Dehumidifying Cassettes and Rotors for Low Humidity or High Ventilation needs!

Type of Eco dry Rotors

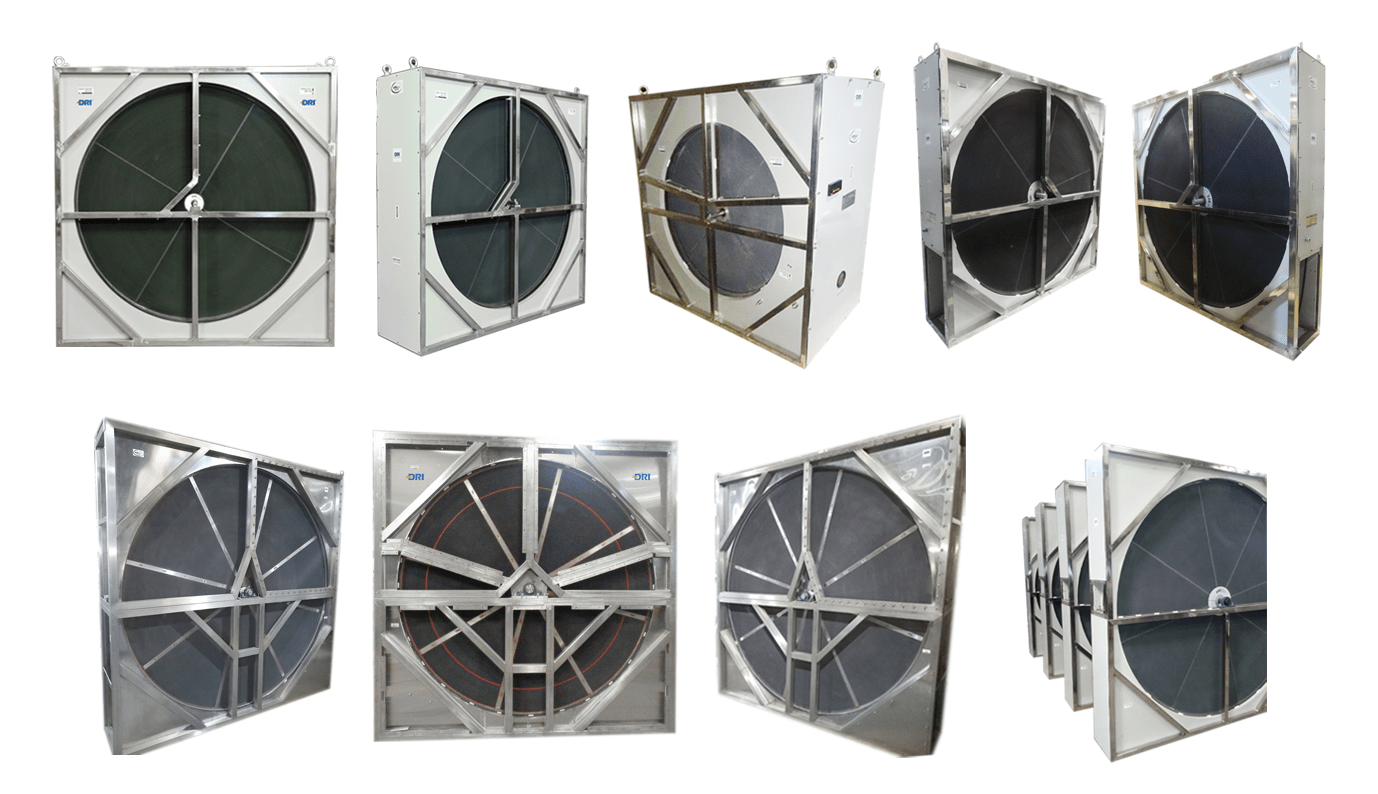

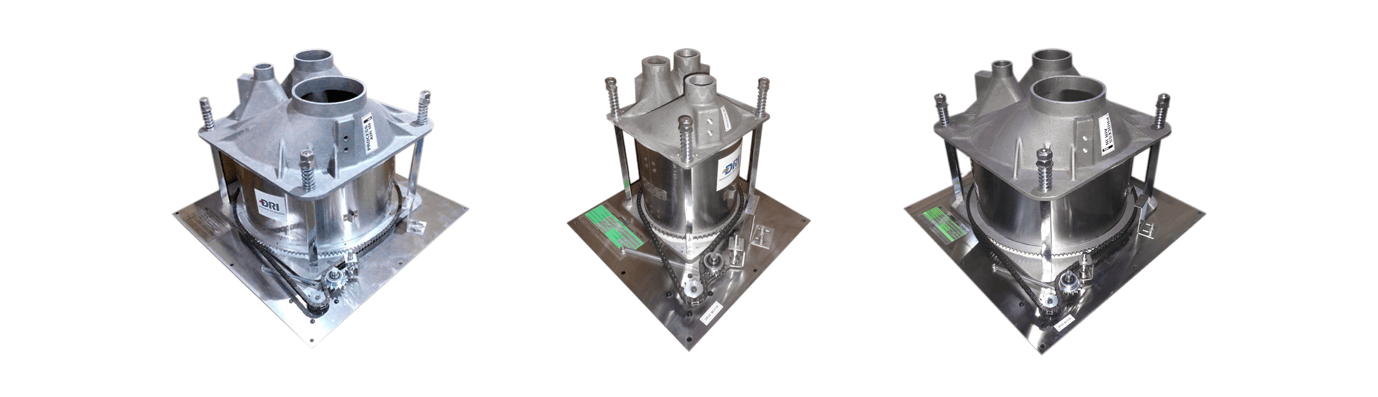

DRI offers desiccant cassettes of all diameters as well. These as standard have a welded stainless-steel structure for strength and excellent leak proof construction. The special bulb sealing system ensures no leakage even at higher pressures. The seals rest on the flange and the full face area of the media is available for dehumidification. The cassettes are available for various configurations including required purge angles. The rotor metal work and cassette casing can be fully in stainless steel if required for food applications. The chain drive system is extremely reliable and comes with gear motors of required electrical specifications and teeth sprockets along the rim of the rotor. These desiccant cassettes are UL 1995 certified. DRI can custom build cassettes in half moon, full moon and segments as per site or dehumidifier unit requirement. Sensors and controls are also available.

DRI also offers a special range of plastic dryer media and cassettes for low dew point plastic resin drying. These cassettes are available in various diameters and depths with high temperature special sealing arrangement and drive arrangements. Kindly contact us for further details.